Today is my first day at my new job working for Ford. I am excited and nervous. I give my shoes one final buff before I stand up to get my coat. It’s an icy, windy morning in Michigan and dirty snow lines the streets of my neighborhood. I try to avoid the filthy slush as I walk the 2 miles to the factory.

The Ford car factory is enormous. Huge squares of floor-to-ceiling windows surround the building’s ground floor. Above it loom five towering smokestacks, huffing smoke into the frigid morning air.

“Stanley Marks reporting for training, sir,” I announce to the floor manager, Mr. Hubbard, when I arrive.

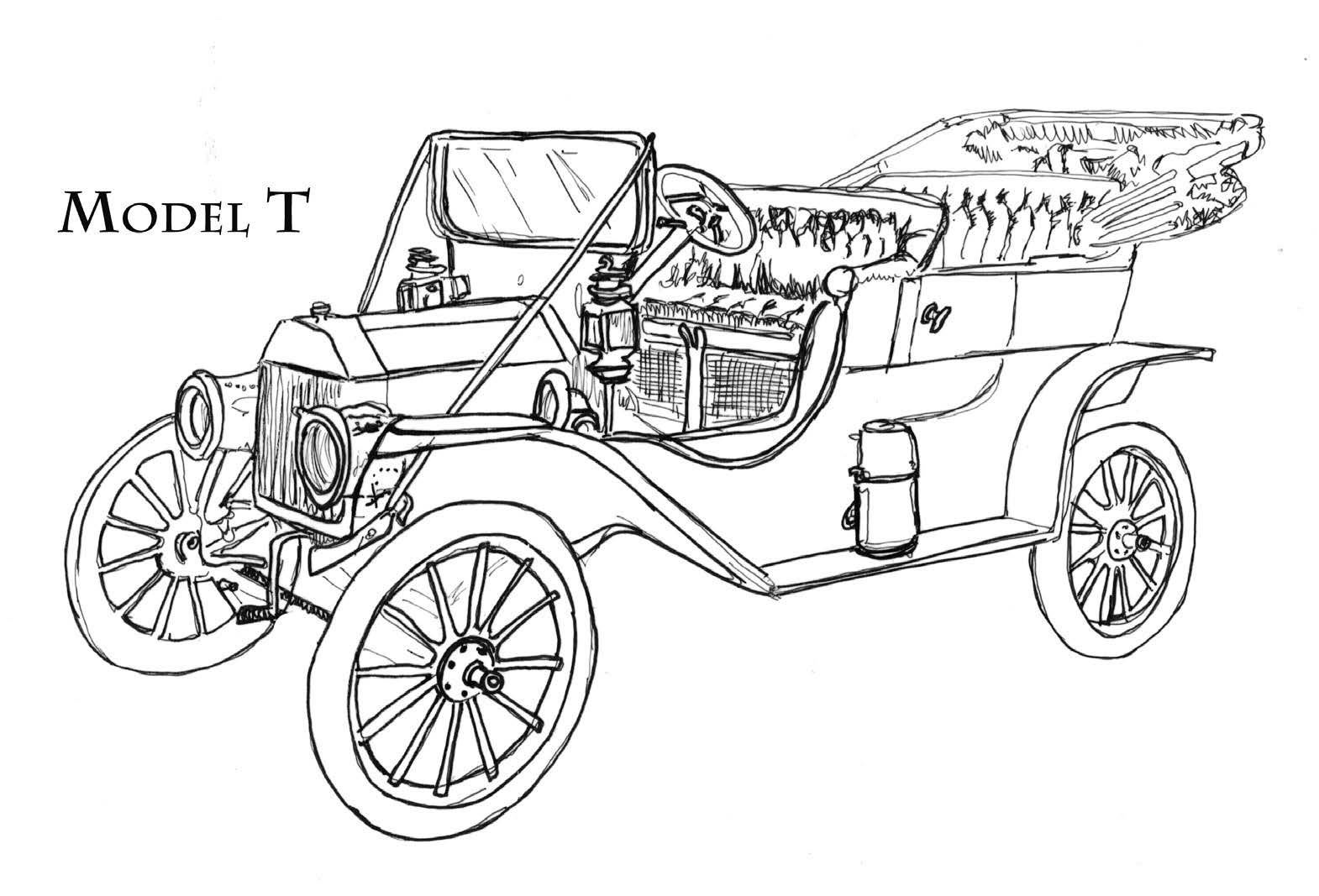

“Hrmm, yes,” says Mr. Hubbard looking me up and down. “Follow me, Mr. Marks. Our factory is the most advanced in the world. When we started, it took us 12 hours to make and build a Model T. Today, we do it in only 6 hours!”

Hundreds of young men are at work, each busy with a different job at different stations along the conveyor belt. The conveyor belt is moving more parts than I can count and at a frantic pace. The air is heavy with the sounds of the machines, the clanging of hammers, and the grunts of the workers. Each man does one job and nothing else, working as fast as he can. No one stops to look at us. They don’t take their eyes from their work—“That’s a sure way to lose a finger, or worse,” says Mr. Hubbard.

Mr. Hubbard explains that my job will be to smooth the edges on the pinion gear. He shows me how to do this using a special tool called a buffer. Then he shows me how to place a finished gear on the conveyor belt when I’m done.

Mr. Hubbard asks me to show him what I’ve learned. When I’m done showing, he clasps my shoulder warmly and says, “Tip top, my boy. Now you’re an expert,” and walks away.

The work is harder than it looks. I stand on my feet for eight hours, doing the same motions over and over again all day long. If I don’t move fast enough, the guys ahead of me on the assembly line begin to protest and complain—they need me to finish so that they can do their jobs.

Leaving the factory, I find the frosty air outside to be much quieter. I walk home and think that I can’t do the same motions for eight hours a day everyday for the rest of my life. If my family didn’t need the money, I would walk home and never come back. But Ford pays better than most anyone else in town. With bonuses, I’ll be able to make $5 a day at Ford’s factory. I’ll be able to feed my family and even take them to an occasional picture show. Maybe one day, if we save up, we’ll even have enough money to buy our own Model T. Then I can take my family out to the country on the weekends. Wouldn’t that be grand!

About BeeLine

About BeeLine